SURFACE PREPARATION

1) Clean the surfaces that will be submitted to it with hydro jets in order to let it completely clean and free from contaminations and rust. The surface must be completely dry, clean, free from dust, grease, paint, oil, oxidation, waste of demolding products.

#HINT: Hard Diluent 004 should be used to clean the application equipment:

- brushes, rollers and rakes

- airless equipment cleaning process;

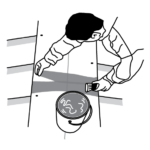

2) Before the liquid mat application, the surface must be even, without cracks and holes. For that reason, in situations where there are materials overlapping (gutters, roofing tiles, ruffs) or holes, apply a strip of self-adhesive reinforcement screen, applying pressure with the roller to soak the entire screen and remove eventual air bubbles.

3) To recover other irregularities, use the sealant Hard MS 435 Roof.

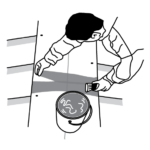

4) it is recommended to apply the Sealant RR 500 ECO SACHET on the bolts heads.

USE MODE:

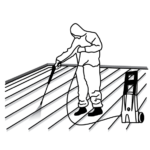

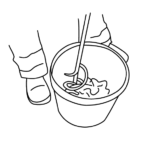

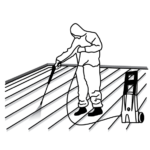

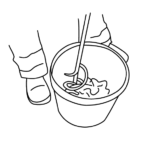

5) Mix the RR 500 ECO, in its can using a spreader or a mechanical stirrer until it is completely homogenized (from 1 to 2 minutes). When the airless system is used, if it is necessary to reduce the viscosity, we recommended to add 10% of Hard Diluent 04, and to clean the equipment after application. Warning: do not use thinner to clean the airless equipment, as it can harm the waterproofing.

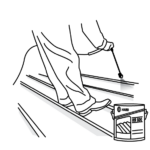

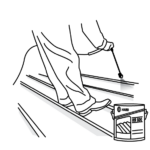

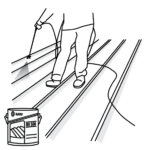

6) Apply the first coat with the microfiber roller, painting brush, broad brush, rake or airless.

7) Wait for the cure time ( 1 to 2 hours)*.

8) Then, apply the second coat**. In the case the coating is insufficient, we recommend applying a third coat.

*The drying time within coats is approximately 1 hour; however, in environments with low humidity, the cure time can be longer. In the case of environments with high humidity, the time tends to decrease.

** In order to assure total coating, it is recommended to use different colors in the first and second coats. The RR 500 ECO mat is available in the colors gray and white.