Proven Quality

Superior quality is synonymous with the Hard brand and it is present in every solution that reaches our customers. This is only possible because excellence is sought at every step of the process, from development to distribution.

Superior quality is synonymous with the Hard brand and it is present in every solution that reaches our customers. This is only possible because excellence is sought at every step of the process, from development to distribution.

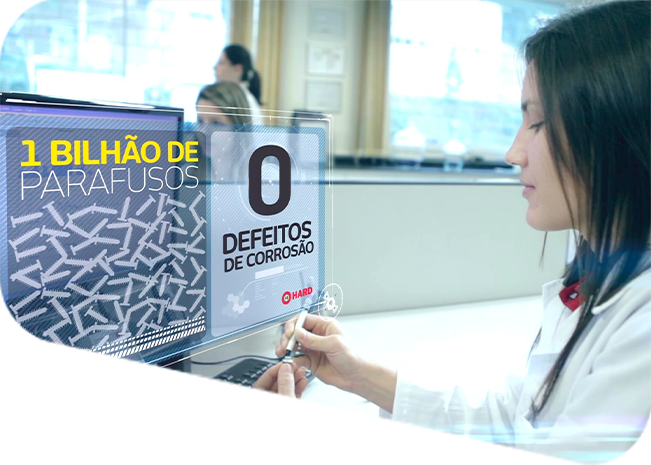

Not only the experience itself proves Hard quality standard, but also the compliance with the most rigorous national and international standards, such as ABNT, ASTM, DIN and ETAG. Among Hard Group’s achievements, there are some highlights:

• First Brazilian fastener company to achieve the rigorous FM Approved certification;

• Homologation by the European Technical Approval, enabling trade in European countries;

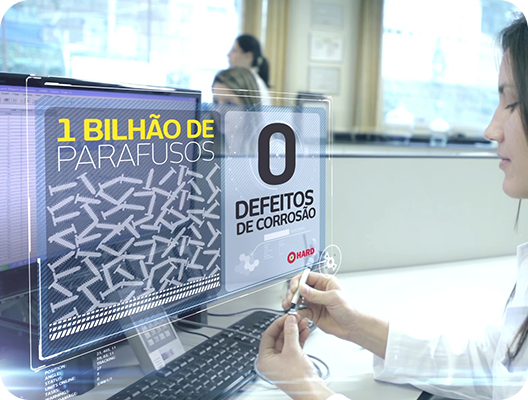

• Delivery of over a billion fasteners for metal roofing without any corrosion defects recorded in its history of high credibility and satisfaction.

Exclusive laboratory for execution of various quality tests, such as Salt Spray (salt spray), Kesternich (acid rain) and UV chamber tests.

Hard solutions are provided with 100% traceability, enabling close monitoring from development to delivery to the customer. Each step is tested and revised as many times as necessary, because, the standard of quality, safety and durability must be in accordance with the needs and requirements of the market.

Offer quality products, seeking innovation, continuous improvement and the effectiveness of the management system, with a commitment to generating customer satisfaction and complying with the requirements and standards applicable to the business.

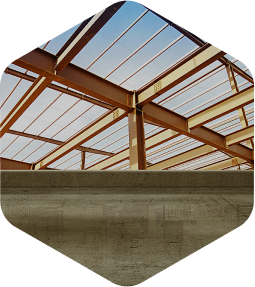

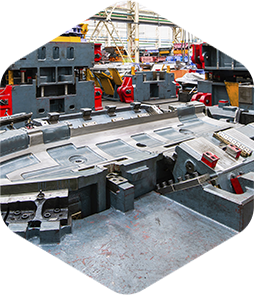

Expert in innovative solutions for Construction and Industry. Discover our operating markets.