Woodcon® Screw

Screw is for fixing tiles in concrete and wood

O parafuso WOODCON é utilizado para fixação de telhas em terças de concreto e madeira.

The WOODCON screw is used for fixing tiles in concrete and wood purlins.

It provides an easy and quick application that does not require hooks. It is manufactured with Ecoseal® coating, ensuring a higher durability for your roof. In addition to that, its unique design ensures that the cover is perfectly sealed.

Replace the hook and be more productive

Its Hi-lo thread system allows lamination directly on concrete and wood, promoting greater agility for the roof assembly process.

High durability

Exclusive Ecoseal® coating on the whole fastener surface, providing better durability for your work.

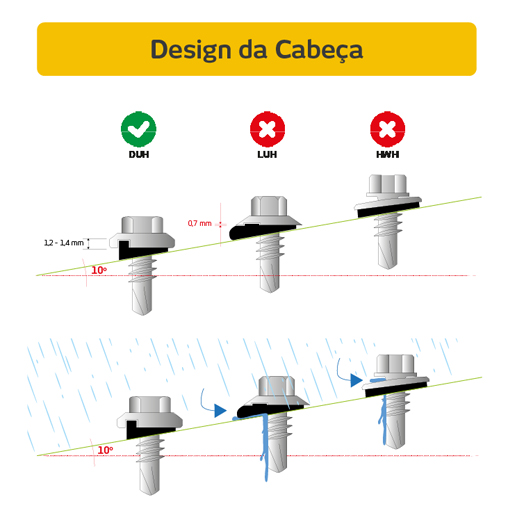

Drip-free coverage

Its flanged head with DUH Design and built-in EPDM washer absorbs up to 10º of inclination, ensuring a leak-free cover