Waterproofing Hard Defense Elastic Fibers

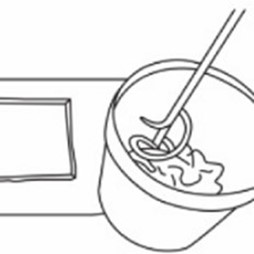

Acrylic Polymer with fibers for elastic waterproofing.

Hard Defense Elastic Fibers is an Acrylic Polymer-based waterproofing with fibers, to be applied as a membrane.

As it has Fibers in its composition, it does not need the use of structuring screen.

After mixed to cement, it results in a waterproofing membrane, resistant to weather and structural movements.

Greater agility in your work

Due to the use of fibers in its formulation, it does not require the use of structuring screen, making the waterproofing application simpler.

Work ready faster

With the product total cure in only 24 hours, it assures higher agility to release the area.

Say good-bye to infiltrations

The product can achieve a good elasticity, and then can follow the structural movements, preventing possible infiltrations.

Hard Group

Company with more than 36 years as national reference in the markets of metallic and precast construction, civil construction, modeling, prototype, and tooling industry. Based in the city of Joinville – Santa Catarina.