Processing Instructions

Since the resin has a moisture inhibitor, it is essential to homogenize the resin can, shaking it a lot before use. If it is not shaken, there will be piece loss, as the mixture will swell and form bubbles.

Separate the containers, spatulas and the load to be used in advance, leave the mold prepared with Z-15 release agent, ready for foundry.

In separate containers, weigh the Resin PC 26 with Hardener G 226 to be used, as well as the amount of load (HF 32 or EF 35 P) according to the proportions described in the technical bulletin.

Add half of the load to the container with the previously weighed resin, then mix it until a good homogenization is obtained. Do not use the spatula that has been previously used to mix the hardener.

Add the other half of the load to the container with the previously weighed hardener, then mix it until a good homogenization is obtained. Do not use the spatula that has been previously used to mix the resin.

After ensuring that the volume to be used is correct, add the hardener mixture to the resin mixture, still ensuring to homogenize it well, so there is no jam.

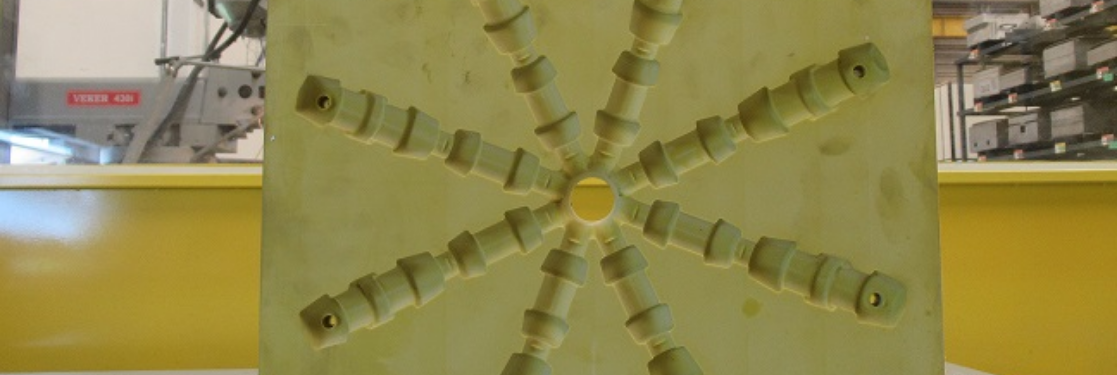

After that, cast the compound to the mold or model, this is important because the using time is around 5 minutes.

EXAMPLE: if you are going to cast a 5 kg model or mold, but you only have containers for 1 kg mixtures, repeat the process above separately for every 1 kg, also leaving the 10 containers prepared in advance, placing the mixture one above the other and not exceeding the gel time of 10 minutes.

NOTE: the resin accepts overlapping layers after drying, to do so, sand the surface to be joined to form grooves for a good anchoring.

Post curing

The post-curing process aims to obtain the maximum mechanical performance that the material can offer. All room temperature cured systems should be post cured for increased performance, especially if they are operating at high temperatures.

After 24 h of curing at room temperature, the material must be heated at 60°C for 15 h, raising the temperature by 10°C/hour. These parameters may change according to the piece size (for larger pieces, the post curing time must be longer). In case of thin layer applications, the post-curing process must be done with the part in the jig.