High performance sealant for swimming pools – iCOM Technology

The MS 426 Sealant for swimming pools is a high performance sealant, developed with iCOM technology, indicated for use in swimming pools, saunas, outdoor showers and other areas that are permanently immersed in water or wet. It is solvent-free and permanently flexible. In addition to that, its formulation guarantees high resistance to chlorine and inhibits formation of fungi.

Chlorine resistant

It is provided with additives that fight against the chlorine effects, ensuring high durability even in unbalanced waters.

Antifungal

Composition with additives that inhibit the formation of fungi, while also being resistant to chemical and cleaning products.

Permanent flexibility

Its noble raw material ensures that the sealant does not lose its flexibility over time.

Benefits

Excellent resistance to chlorine

Excellent resistance to chlorine

Antifungal

Antifungal

Permanent flexibility

Permanent flexibility

Excellent aging resistance due to chlorine and water pH resistant additives

Excellent aging resistance due to chlorine and water pH resistant additives

Applicable in green construction works, isocyanate and solvent free product

Applicable in green construction works, isocyanate and solvent free product

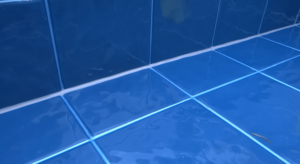

Applications

Package

- 260ml cartridge (Box with 12 pieces)

Colors

- Gray

- White

PROPERTIES

- Consistency: Thixotropic (doesn’t seep)

- Worktime: 20-60 min

- Hardness (DIN 53505): 25-35 Shore A

- Movement capacity: 50%

- Performance: 9.3 m (5×5 mm joint with 1:1 form factor)

NOTES

- Application temperature (surface): 5°C to 40°C

- Work temperature: -40°C to 100°C

- Storage temperature: 5°C to 35°C

- Storage life: 12 months

- For application in environments with humidity, please refer to our technical department

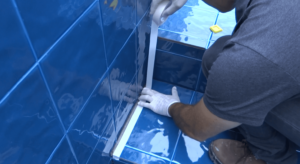

| STEP BY STEP – APPLICATION OF MS 426 SEALING FOR SWIMMING POOLS |

1 – Carry out a thorough clean of the surfaces and the joint to be filled. It should be free from dust, oil and loose particles.

NOTE: in case of maintenance, there should be no residues of sealants and silicones

2 – Glue the masking tape on the edges of the joint for a better final finish.

3 – Place the Tarucel Hard depth delimiter at the bottom of the joint.

NOTE: the tarucel must have a diameter 20% greater than the joint width.

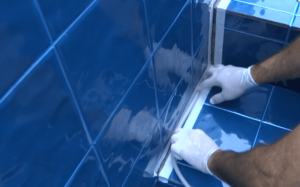

4 – Cut the seal tube, place it on the applier, then attach the nozzle and cut it diagonally (at 45°) in the desired thickness.

5 – Apply the sealant continuously, only once.

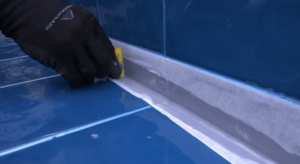

6 – Finish with a spatula and neutral detergent.

7 – Immediately remove the masking tape, while the sealant is still fresh.

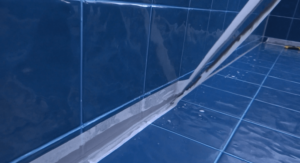

8 – Wait 72 hours to fill the swimming pool.

Online calculator

Online calculator that simplifies the calculation for the amount of sealants and adhesives to be used in your work.

Calculate now

Related Products

Conheça Nossos ProdutosBudget for Company

Do you want to buy for CNPJ? Click the button below and speak to one of our experts.

Request a quoteFind a Store

We are present throughout Brazil, click the button below and find the store closest to you.

Find storeBuy Online

You can buy directly from our online store and receive it at your home. More comfort and agility for you.

Go to online store