Lentil Hex Head Screw – FM Approved

STEEL FASTENERS WITHOUT SEALING

Self-drilling screw without sealing made of carbon steel with white zinc plating or Ecoseal 10k. Suitable for fixing clips for zipped tiles and metallic components for truck and bus bodies.

Benefits

Drilling, fixing and locking in only one operation

Drilling, fixing and locking in only one operation

Better productivity, eliminating the need of nuts and lock washer

Better productivity, eliminating the need of nuts and lock washer

It replaces rivets on side closures

It replaces rivets on side closures

Its rounded finish facilitates floor traffic

Its rounded finish facilitates floor traffic

Does not require retighten

Does not require retighten

Screws with FM Approved certification

Screws with FM Approved certification

Applications

METALIC LINE – SIXLOB SCREW (LENTIL HEAD – FM APPROVED)

| DESCRIPTION | DRILL BIT | APPLICATION RANGE (MM) | COATING | TIGHTENING WRENCH | U.M. | FRACTIONED AMMOUNT PER PACKAGE (PC) | MASTER AMMOUNT PER PACKAGE (PC) |

| PB 10 – 16X3/4” | TCP3 | 2.79 – 4.45 | WHITE ZINC PLATED | TORX 25 | CX. | 700 | 7500 |

| PB 10 – 16X3/4” | TCP3 | 2.79 – 4.45 | ECOSEAL 10K | TORX 25 | CX. | 700 | 7500 |

| PB 1/4 – 14X3/4” | TCP3 | 2.79 – 6.35 | WHITE ZINC PLATED | TORX 30 | CX. | 400 | 4000 |

| PB 1/4 – 14X3/4” | TCP3 | 2.79 – 6.35 | ECOSEAL 10K | TORX 30 | CX. | 400 | 4000 |

| PB 1/4 – 14X1” | TCP3 | 2.79 – 6.35 | WHITE ZINC PLATED | TORX 30 | CX. | 300 | 3000 |

| PB 1/4 – 14X1” | TCP3 | 2.79 – 6.35 | ECOSEAL 10K | TORX 30 | CX. | 300 | 3000 |

| PB 1/4 – 20X1” * | TCP3 | 2.79 – 6.35 | WHITE ZINC PLATED | TORX 30 | CX. | 300 | 3500 |

| PB 1/4 – 14X1.5/8” | TCP3 | 2.79 – 6.35 | WHITE ZINC PLATED | TORX 30 | CX. | 200 | 2000 |

| PB 1/4 – 14X1.5/8” | TCP3 | 2.79 – 6.35 | ECOSEAL 10K | TORX 30 | CX. | 200 | 2000 |

*Serrated head

COMPOSITION:

Material: Carbon steel with thermal treatment

| FINISHING | LAYER THICKNESS | CORROSION RESISTANCE | |

| SALT-SPRAY¹ | KESTERNICH² | ||

| WHITE ZINC PLATED | 5 MICRONS | 48 HOURS | N/A³ |

| ECOSEAL 10K | 10 MICRONS | 240 HOURS | 10 CYCLES |

1 – ASTM B117, ABNT NBR 8094 and DIN 50021 Standards (red corrosion)

2 – DIN 50018 Standard (admitting 15% red corrosion on screw head)

3 – The test does not apply to the sample. Duration is less than 1 cycle.

Related Products

Conheça Nossos ProdutosFrequently Asked Questions

The problems of tip burning, can be related to the following situations:

- a) High rotation (tip firing): The high rotation of the equipment can cause high wear on the screw tip, due to the high friction index, thus generating the breakage of the cutting rod of the screw tip.

- b) Screw performs two operations at the same time (tip breaking): If the screw is generating two operations at the same time (e.g.: drilling and fastening), the process may slow down the rotation of the screw at the moment of drilling, generating tip burn.

- c) Extension too long: if the extension is too long, it may decrease the voltage of the screwdriver, generating a decrease in rotation, making the drilling process more difficult, and causing the tip to burn.

- d) Boring holes outside the specification (tip flaring): The screw must pierce the specified range of each tip, according to the Hard Technical Bulletin. Drilling above this range causes the tip to burn out.

SOLUTION

The possible solutions for tip burning are listed in the following alternatives:

- a) Use the appropriate equipment, according to Hard specification, of maximum rotation of 2500 RPM and 15Nm of wrench.

- b) During the installation process, the screw should perform one operation at a time, such as:

1º) Drilling;

2º) Laminate;

3º) Screw;

This prevents loss of speed during the process and, consequently, burning of the tip.

- c) Work with extensions of a maximum of 2 meters, preventing loss of tension.

- d) Work according to the drilling range specified in the Hard’s Technical Report, checking the comparative between: TIP TYPE X PURLIN THICKNESS.

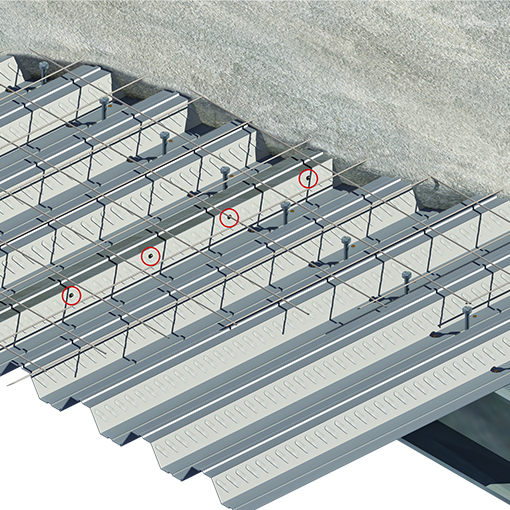

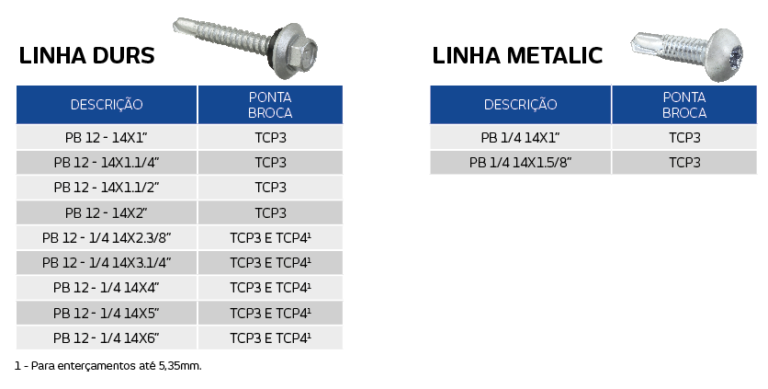

Currently the Durs Line and Metalic Line items are FM Approved certified, but other products are in the certification process. Check the table below to see which items have already been approved.

All of our products follow the same quality control criteria, therefore all of Hard’s product line offers high durability and resistance.

Budget for Company

Do you want to buy for CNPJ? Click the button below and speak to one of our experts.

Request a quoteFind a Store

We are present throughout Brazil, click the button below and find the store closest to you.

Find storeBuy Online

You can buy directly from our online store and receive it at your home. More comfort and agility for you.

Go to online store