Flanged Hex Head Screw – FM Approved

STEEL FASTENERS WITHOUT SEALING

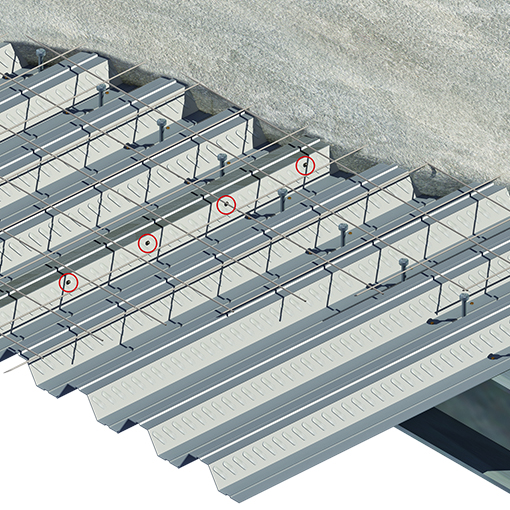

Line of self-drilling fasteners, suitable for fixing metallic sheets, such as fixing and joining steel frame profiles and profiles for ventilated facades, fixing of clips for zipped tiles and joining steel deck shapes. Available in white zinc and Ecoseal coating options. It is provided with a hex head, which makes it easier to fit the socket, and the application as well.

Benefits

Fixing and drilling in only one operation

Fixing and drilling in only one operation

Does not loosen with vibration

Does not loosen with vibration

High drilling speed

High drilling speed

Screws with FM Approved certification

Screws with FM Approved certification

Applications

METALIC LINE – HEXDRILL SCREW (FLANGED HEX HEAD) – FM APPROVED

| DESCRIPTION | DRILL BIT | APPLICATION RANGE (MM) | COATING | TIGHTENING WRENCH | U.M. | FRACTIONED AMMOUNT PER PACKAGE (PC) | MASTER AMMOUNT PER PACKAGE (PC) |

| PB 8 – 18X1/2” | TCP2 | 0.89 – 2.54 | WHITE ZINC PLATED | 1/4” | CX. | 1000 | 10000 |

| PB 8 – 18X1/2” | TCP2 | 0.89 – 2.54 | ECOSEAL 10K | 1/4” | CX. | 1000 | 10000 |

| PB 10 – 16X3/4” | TCP3 | 2.79 – 5.35 | WHITE ZINC PLATED | 5/16” | CX. | 600 | 6000 |

| PB 12 – 14X3/4” | TCP3 | 2.79 – 5.35 | WHITE ZINC PLATED | 5/16” | CX. | 300 | 5000 |

| PB 12 – 14X7/8” | TCP1 | 0.89 – 2.28 | WHITE ZINC PLATED | 5/16” | CX. | 250 | 5000 |

| PB 12 – 14X7/8” | TCP1 | 0.89 – 2.28 | ECOSEAL 10K | 5/16” | CX. | 250 | 5000 |

| PB 12 – 14X1” | TCP3 | 2.79 – 5.35 | WHITE ZINC PLATED | 5/16” | CX. | 400 | 4000 |

| PB 1/4 – 14X7/8” | TCP1 | 0.89 – 2.28 | WHITE ZINC PLATED | 5/16” | CX. | 400 | 4000 |

COMPOSITION:

Material: Carbon steel with thermal treatment

| FINISHING | LAYER THICKNESS | CORROSION RESISTANCE | |

| SALT-SPRAY¹ | KESTERNICH² | ||

| WHITE ZINC PLATED | 5 MICRONS | 48 HOURS | N/A³ |

| ECOSEAL 10K | 10 MICRONS | 240 HOURS | 10 CYCLES |

1 – ASTM B117, ABNT NBR 8094 and DIN 50021 Standards (red corrosion)

2 – DIN 50018 Standard (admitting 15% red corrosion on screw head)

3 – The test does not apply to the sample. Duration is less than 1 cycle.

Related Products

Conheça Nossos ProdutosFrequently Asked Questions

The problems of tip burning, can be related to the following situations:

- a) High rotation (tip firing): The high rotation of the equipment can cause high wear on the screw tip, due to the high friction index, thus generating the breakage of the cutting rod of the screw tip.

- b) Screw performs two operations at the same time (tip breaking): If the screw is generating two operations at the same time (e.g.: drilling and fastening), the process may slow down the rotation of the screw at the moment of drilling, generating tip burn.

- c) Extension too long: if the extension is too long, it may decrease the voltage of the screwdriver, generating a decrease in rotation, making the drilling process more difficult, and causing the tip to burn.

- d) Boring holes outside the specification (tip flaring): The screw must pierce the specified range of each tip, according to the Hard Technical Bulletin. Drilling above this range causes the tip to burn out.

SOLUTION

The possible solutions for tip burning are listed in the following alternatives:

- a) Use the appropriate equipment, according to Hard specification, of maximum rotation of 2500 RPM and 15Nm of wrench.

- b) During the installation process, the screw should perform one operation at a time, such as:

1º) Drilling;

2º) Laminate;

3º) Screw;

This prevents loss of speed during the process and, consequently, burning of the tip.

- c) Work with extensions of a maximum of 2 meters, preventing loss of tension.

- d) Work according to the drilling range specified in the Hard’s Technical Report, checking the comparative between: TIP TYPE X PURLIN THICKNESS.

FM Approved is a certification granted by FM Approvals, an organization linked to FM Global, which has laboratories and teams of more than 1500 engineers able to test and reproduce the most difficult meteorological phenomena, recreating hurricane-force winds (258km/h) and testing the resistance of building materials, particularly roofing systems. The tests performed range from verifying the product design and/or specification to quality controls and installation.

Some of the quality system requirements evaluated are: procedures for incoming inspection of raw materials and manufacturing quality control, engineering documentation, measurement systems, procedures for traceability, and anomaly handling. FM Approvals is recognized and respected around the world. FM Approved certification assures customers that a product or service has been rigorously tested and complies with the highest national and international standards.

WHAT IS GLOBAL FM?

Global FM is an insurance company specialized in the prevention of property claims through the use of loss prevention engineering. Founded in 1835, the organization has a strong presence in more than 130 countries, and a third of the companies in the American “Fortune 1000” are its customers.

Melhor custo-benefício e garantia de que os produtos empregados na obra possuem padrões de qualidade, critérios de segurança e desempenhos técnicos aprovados no mundo todo.

É indispensável, portanto, uma empresa observar, no momento das especificações dos projetos, que os custos com fixadores na obra são irrisórios se comparados aos prejuízos resultantes da danificação de máquinas, equipamentos, estoques de matérias-primas e produtos acabados, causados pelo arrancamento da cobertura em uma tempestade ou vendaval.

Budget for Company

Do you want to buy for CNPJ? Click the button below and speak to one of our experts.

Request a quoteFind a Store

We are present throughout Brazil, click the button below and find the store closest to you.

Find storeBuy Online

You can buy directly from our online store and receive it at your home. More comfort and agility for you.

Go to online store