Injectable Vinylester-Based Structural Chemical Anchor

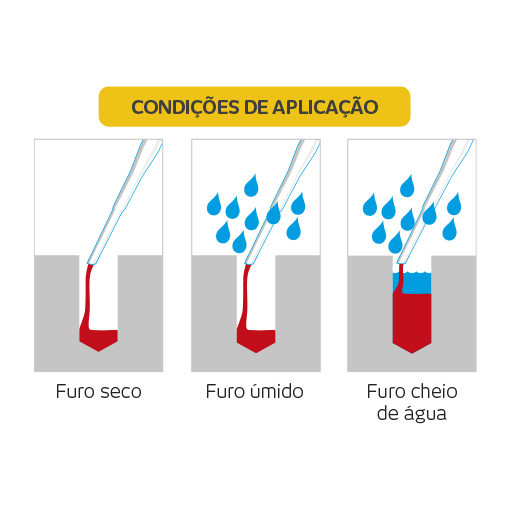

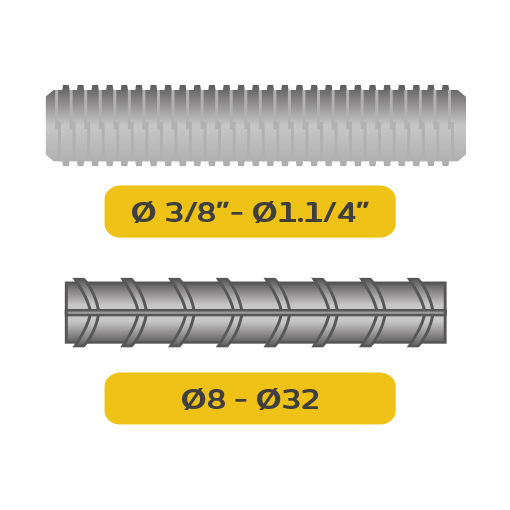

The injectable adhesive VI 1101 is a high-performance and quick cure structural adhesive for anchorage of threaded bars and rebars in concrete and masonry. It has international certifications and approvals, ensuring quality to your work. In addition, it is possible to easily size you ideal anchorage system through the Hard DesignFix software.

The fire test

VI 1101 has the German certification F120 (Feuerwiderstansklasse), that certifies that the attachment was submitted to a fire test for 120 minutes without losing its physical and chemical properties. Therefore, the anchorage withstands 2 hours of flames attack.

It contributes to the safety against fire estimated by the legislation, regulated by the permit issued by the Fire Department (Fire Department Inspection Certificate – AVCB).

Quality assurance

VI 1101 has international approval that assures higher safety to your work. The certification ETA – 13/0564 – Option 1, assures that the VI 1101 passes tough the most comprehensive anchorage battery of tests, thus comprising the loads for application in fissured concrete, from 20 to 50 Mpa, combined traction and shearing loads, distance of edges and between anchorages, and application in regions of seismic tremor and high vibration rates.

Sizing with no difficulties

Using the injectable adhesive VI 1101 , you will have exclusive access to the Hard DesignFix software to easily size the ideal anchorage system specifications to your project, according to the main international standards.

Benefits

High productivity and performance

High productivity and performance

Chemical anchorage with international certifications

Chemical anchorage with international certifications

Excellent resistance to chemical substances

Excellent resistance to chemical substances

It waterproofs the hole

It waterproofs the hole

It allows applications in extreme environments, in addition to proximity to the sea (saline)

It allows applications in extreme environments, in addition to proximity to the sea (saline)

Resistance to high temperatures

Resistance to high temperatures

Without styrene, can be applied in green works

Without styrene, can be applied in green works

Strongest quick cure system in the market

Strongest quick cure system in the market

Calculation and sizing software

Calculation and sizing software

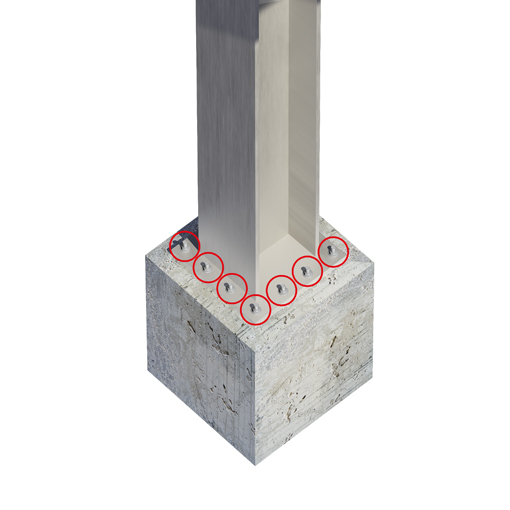

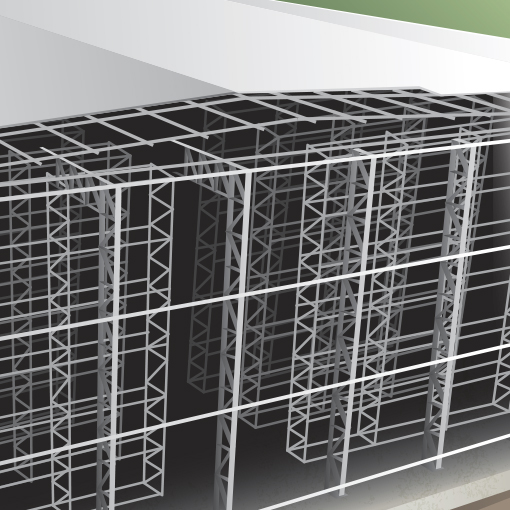

Applications

Package

- Cartridge 345 ml

- Box with 12 pieces

COMPOSITION:

- Vinylester

PROPERTIES:

- Consistency: Pastry (it does not leak)

- Mix ratio: 10:1

CURE TIME

| BASE MATERIAL TEMPERATURE | WORK TIME | CURE TIME – DRY BASE | CURE TIME – WET BASE |

| -10ºC1 | 90 MINUTES | 24 HORAS | 120 HORAS |

| -5ºC | 90 MINUTES | 14 HOURS | 28 HOURS |

| 0ºC | 45 MINUTES | 7 HOURS | 14 HOURS |

| 5ºC | 25 MINUTES | 2 HOURS | 4 HORAS |

| 10ºC | 15 MINUTES | 80 MINUTES | 160 MINUTES |

| 20ºC | 6 MINUTES | 45 MINUTES | 90 MINUTES |

| 30ºC | 4 MINUTES | 25 MINUTES | 50 MINUTES |

| 40ºC | 2 MINUTES | 20 MINUTES | 40 MINUTES |

1 – For installation in base material with temperature within -10ºC and -5ºC, cartridges should be

stored at temperatures within 15ºC and 25ºC.

NOTES:

- Base material temperature for installation: -10°C to 40°C

- Product temperature for application: minimum: 5°C, excellent: 20°C

- Material temperature after cured: -40°C to 120°C

- Storage temperature: 5°C to 25°C

- Shelf life: 18 months

Online calculator

Online calculator that simplifies the calculation of the amount of chemical anchor to be used in the project and/or in the work.

Calculate now

Related Products

Conheça Nossos ProdutosBudget for Company

Do you want to buy for CNPJ? Click the button below and speak to one of our experts.

Request a quoteFind a Store

We are present throughout Brazil, click the button below and find the store closest to you.

Find storeBuy Online

You can buy directly from our online store and receive it at your home. More comfort and agility for you.

Go to online store