Structural epoxy-based chemical adhesive

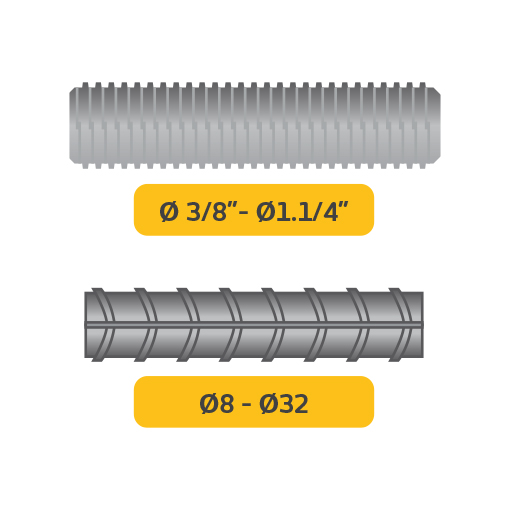

Epoxy Pro injectable adhesive is indicated for rebars anchorage. It is supplied with a mixing nozzle that assures an easy and quick application. In addition, it has the warranty of tabulated loads due to the instantaneous components mix.

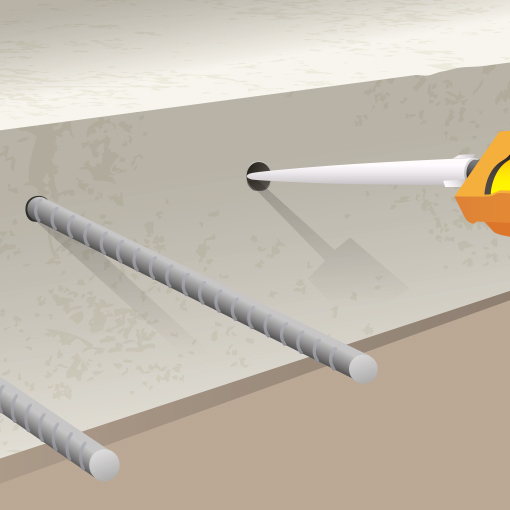

Installation without complication

The static mixing nozzle makes the components mix at the time of application, without the need for pre-mixture as in the epoxy adhesives in conventional cans.

High productivity

Its injectable system assures high productivity in our work avoid wasting materials and time.

Loads warranty

The instantaneous components mix promotes the correct dosage between the resin and hardener, providing warranty for the tabulated loads.

Former: Hardfix Epoxy Pro. The name has changed, but you don’t need to worry: the product remains with the same quality as always. And the most important: the formula remains the same.

Benefits

Quick and easy application

Quick and easy application

Indicated for dynamic loads

Indicated for dynamic loads

Indicated for applications that do not require technical approvals

Indicated for applications that do not require technical approvals

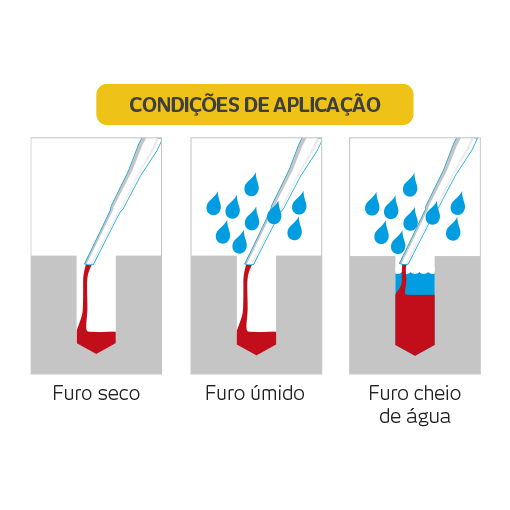

It does not leak (thixotropic ), and can be applied in holes on the ceiling

It does not leak (thixotropic ), and can be applied in holes on the ceiling

High productivity

High productivity

Without styrene, can be applied in green works

Without styrene, can be applied in green works

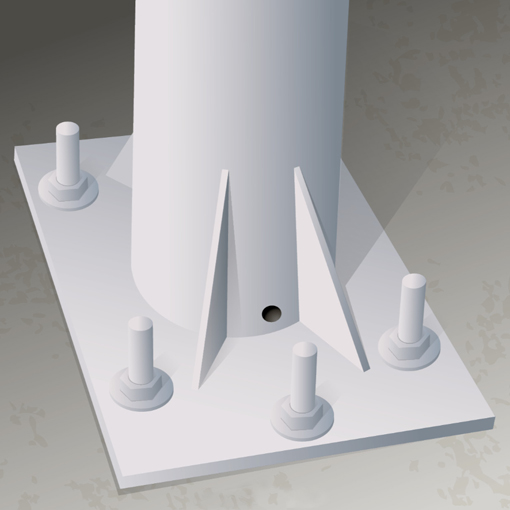

Applications

Package

- Cartridge 600 ml

PROPERTIES:

- Consistency: Pasty (does not leak)

- Mixture ratio: 1:1

CURE TIME

| BASE MATERIAL TEMPERATURE | WORK TIME | CURE TIME – DRY BASE | CURE TIME – WET BASE |

| 5°C | 180 MINUTES | 50 HOURS | 100 HOURS |

| 10°C | 120 MINUTES | 24 HORAS | 48 HOURS |

| 20°C | 30 MINUTES | 10 HOURS | 20 HOURS |

| 30°C | 20 MINUTES | 6 HOURS | 12 HOURS |

| 40°C | 12 MINUTES | 4 HORAS | 8 HOURS |

NOTES:

- Base material temperature for installation: 5°C to 40°C

- Product temperature for application: Minimum: 5°C – Excellent: 20°C

- Material temperature after cured: -40°C to 65°C

- Storage temperature: 5°C to 35°C

- Shelf life: 24 months

- The product can be stored in a dry, clean place, away from heat sources, sparkles and flames.

Online calculator

Online calculator that simplifies the calculation of the amount of chemical anchor to be used in the project and/or in the work.

Calculate now

Related Products

Conheça Nossos ProdutosBudget for Company

Do you want to buy for CNPJ? Click the button below and speak to one of our experts.

Request a quoteFind a Store

We are present throughout Brazil, click the button below and find the store closest to you.

Find storeBuy Online

You can buy directly from our online store and receive it at your home. More comfort and agility for you.

Go to online store