Membrane for internal areas waterproofing

HARD FLEXPREN is a ready-to-use membrane to waterproof internal areas. Developed from MS Polymer® technology, it provides high performance, higher productivity and excellent adherence. It forms a waterproof membrane with high elasticity after applied.

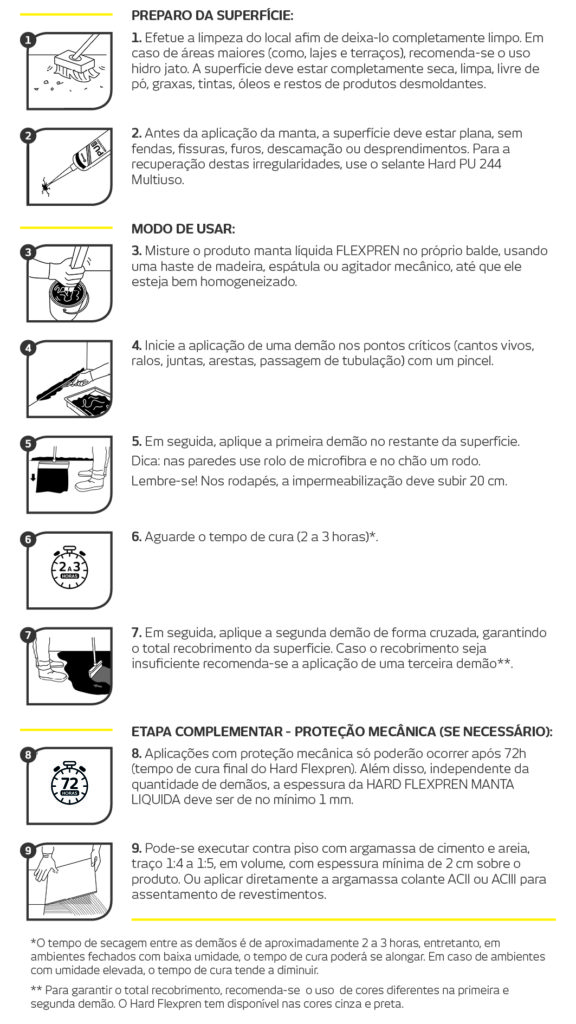

To apply it in slabs and other external areas, some mechanical protection will be required (mechanical laying, made of stones or sub-floor).

Benefits

Ready-to-use product (single component, no need to dilute in water or solvents).

Ready-to-use product (single component, no need to dilute in water or solvents).

Quick drying, only 2h between coats and 24h hours for the total cure.

Quick drying, only 2h between coats and 24h hours for the total cure.

Easily applied, does not need reinforcement screen.

Easily applied, does not need reinforcement screen.

Higher agility when applying the second coat.

Higher agility when applying the second coat.

Higher flexibility, replacing the conventional acrylic and cement mats.

Higher flexibility, replacing the conventional acrylic and cement mats.

Free from solvents, isocyanate and styrene.

Free from solvents, isocyanate and styrene.

No need for primer.

No need for primer.

No need to use torch, replacing the asphalt mat.

No need to use torch, replacing the asphalt mat.

Applications

Package

Available in cans with 4 kg, in gray and black color.

- Consistency: Self-leveling;

- Work time: From 2 to 3 hours (between coats);

- Final cure: 24 hours (for applications with mechanical protection, wait 72h);

- Density: 1.6 g/cm³;

- Application temperature (surface): 5 to 40ºC;

- Storage temperature: 5 to 25ºC;

- Shelf life: 12 months;

- Yield: (can with 4 kg – 2 coats) Application with Brush, Roll, or Rake: 5 m² or 0.8kg/m²;

- Yield can vary according to the substrate porosity and the place to be applied.

Related Products

Conheça Nossos ProdutosFrequently Asked Questions

The reinforcement mesh is used to increase the mechanical resistance of the waterproofing, so it is generally used in critical points, such as sharp corners, vertical edges, horizontal edges, drains, etc.

However, the waterproofing Fexpren doesn’t need the reinforcement mesh. The product was developed using MS Polymer® technology, which after curing forms a flexible, waterproof membrane with excellent adhesion to concrete, ensuring complete waterproofing in the applied area and doesn’t need a reinforcement screen.

By doing that, the use of the reinforcement mesh is an option if you want to have a double guarantee of waterproofing, especially in areas where there is more cracking, such as expansion joints.

Do you want to learn more about it? Watch our video “Teste de impermeabilização: Manta Flexpren x Manta Acrílica”. In this video a test was performed and proved in practice why the Flexpren blanket does not need a reinforcement cloth.

Flexpren waterproofing can be used in outdoor areas as long as it is not directly exposed to the sun. In these cases, we recommend the application of a mechanical protection such as counter-flooring or ceramic tile laying.

Yes, Flexpren waterproofing material can be used as long as it is not directly exposed to the sun, in these cases we recommend the application of a mechanical protection.

Is there any products left? No problem, you can store the waterproofing agent to use again later. Do you want to know how? Check out our tips.

The Flexpren and RR 500 ECO waterproofing cures with air humidity, i.e. the greater the contact with air, the faster it will dry. That’s why, it is fundamental to close the can correctly, avoiding this contact. To do this, clean off any products residue on the edge of the package, as it can prevent it from closing completely and allowing air in. Then slowly fit the lid on, without using hammers or other tools, so as not to dent it. That’s it! You can store the waterproofing agent until it expires.

Another very important tip is not to leave the can open during the waterproofing process. So, remove the product that is to be used and close the package immediately afterwards.

Don’t be alarmed if when you reopen the can there is a film over the product. This is because the formation of this membrane is inevitable, since contact with oxygen has occurred. But if you have followed the tips above, just remove and apply the product as normal.

By doing it, you guarantee quality and avoid waste in the use of your Hard waterproofing material.

Yes! We did the pull-out tests taking into consideration the NBR 13755 standard for facades (CERAMIC FACADE AND EXTERNAL WALL FINISHING WITH THE USE OF COLLECTING MORTAR). This standard requests a load of 0.5 MPa in a sample with a diameter of 50mm, and in these tests the results were excellent.

Budget for Company

Do you want to buy for CNPJ? Click the button below and speak to one of our experts.

Request a quoteFind a Store

We are present throughout Brazil, click the button below and find the store closest to you.

Find storeBuy Online

You can buy directly from our online store and receive it at your home. More comfort and agility for you.

Go to online store