Read how an agricultural equipment industry saved money in the production of models, molds and core cases and still gained in productivity. All this by substituting the aluminum of the raw material for the Polyurethane plates.

Problem

In foundry, models, molds and core boxes are used in the manufacture of a part. To produce these items, the company suffered from depending on a single supplier in the region. In addition to concerns about possible delivery delays, costs were an issue as well, as there was not even the option of budgeting with another supplier and comparing prices.

Solution

By acquiring its own CNC milling machine, a machine capable of modeling a part from a sheet or block of material, the company took the first step towards solving its problem. By doing this, they would no longer depend on third parties to manufacture their models, molds and core boxes.

When they found out about this acquisition, our technical consultants Edenilson Massagardi and Pedro Sebastiany identified that they could achieve even better results if they changed the raw material of the models and core boxes. This is because, by replacing aluminum with a Polyurethane plate, the company would gain in efficiency, because the ease of machining guarantees an average reduction of 50% in production time. In addition to that, its accuracy would ensure the quality of the parts and, as it is a lighter material, improve ergonomics for employees.

But such a change could not be made overnight, as the company only knew aluminum as a standard material for this purpose and was used to its use.? Therefore, after studies, a comparative test was carried out between a piece produced with Polyurethane plate and another produced with aluminum.

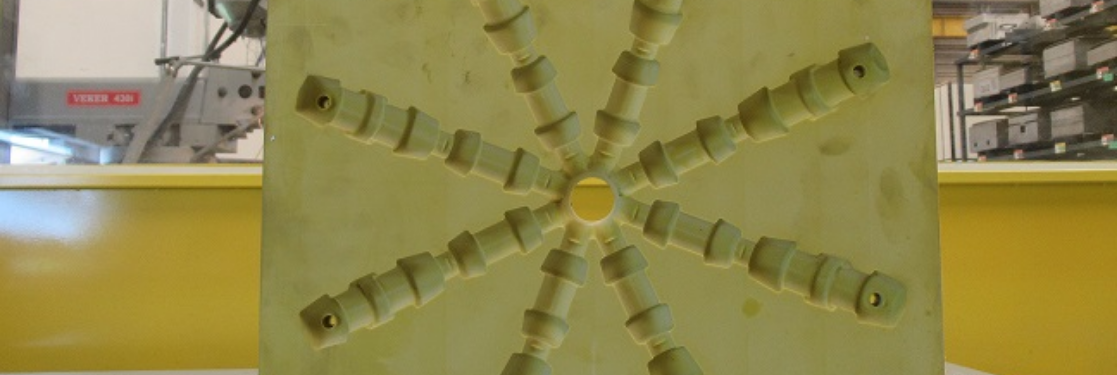

Produced by third parties, the aluminum item would take 12 days to be ready, while the agricultural equipment industry produced in six hours with the PU plate, even with the company’s employees without much experience with the material. It means that in the same period of time that the old supplier produced a single part, the company would be able to produce 48 similar items itself.

In addition to this, in aluminum, the tool would cost R$ 7,500.00. With the use of the Polyurethane plate, the same item cost R$ 2,500.00, resulting in a savings of R$ 5,000.00 in just one piece. Considering these values, the investment recovery in the CNC milling machine was estimated in seven months.

Currently, they work with the WB-1404 plates for the manufacture of core boxes and theWB-1460 for the production of models, both distributed exclusively by Hard. ?In addition to that, the company started to use PC26 Resin with G226 Hardener and the Z15 LC Release Agent to manufacture models. As the Resin and Hardener cure quickly, demolding takes up to one hour, which shortens the parts replication time. Its perfect reproduction of details also ensured that the company gained in the quality of the models, consequently impacting the final result of the piece produced.

Conclusion

In addition to the financial gain, by changing the raw material of the male models and boxes, the agricultural equipment manufacturer also gained in productivity. Now, they can produce 48 items in the same period of time it would take to receive just one in aluminum from the supplier, with an average savings of R$ 5,000.00 in each unit. It means a reduction of approximately 66% in the value of each piece. All this without losing the quality of the models, which has a great impact on the final result of the piece produced.

If, at first, the company’s objective was just not to depend on a supplier anymore, with the right changes they managed to optimize their production process. In addition to saving time and money, a leap in quality was made, ensuring the perfect reproduction of details in your pieces.?

Are you curious to know how Hard can make your production routine easier? Just contact us.

?

*Case study carried out in September 2019.

Comentários

Ainda não há comentários. Seja o primeiro a comentar.