Thixotropic epoxy system for industrial maintenance with similar characteristics as aluminum

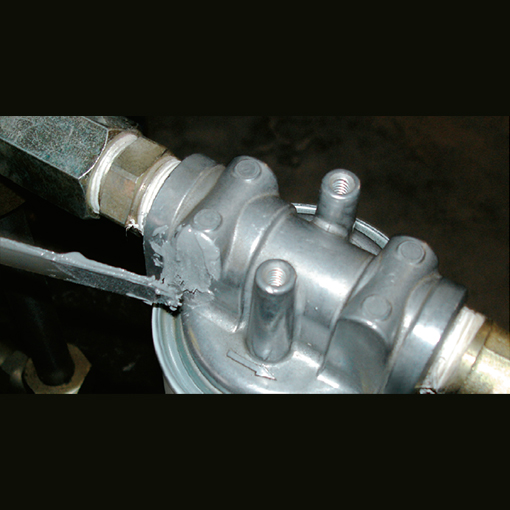

Changed epoxy system, containing aluminum filler resistant to high temperatures. It can be machined, sanded, driller and ground. It has characteristics similar to aluminum. It is indicated to recover aluminum cast or injected parts; molds maintenance and repair. Applicable with spreader and at thickness of 5 to 10 mm.

Benefits

Repair at cold

Repair at cold

It can be sanded, machined and drilled

It can be sanded, machined and drilled

Cure at room temperature

Cure at room temperature

Characteristics similar to aluminum

Characteristics similar to aluminum

Applications

Package

- Aluminum Repair Resin (1,500 kg)

- Aluminum Repair Hardener (0.190 kg)

- Mixture ratio in mass: 100 g of resin to 12.5 g of hardener

- Mixture color: Gray

- Work time at 25ºC: 15 minutes

- Total cure time at 25ºC: 72 hours

- Recommended thickness: 5 – 10 mm

Processing Instructions

The surface to be coated with ALUMINUM REPAIR should be clean, sanded and preferentially dry-sandblasted to obtain a good resin adherence.

On locations where the product adherence is not desired, apply two layers of demolding Z 15 LC.

The ALUMINUM REPAIR HARDENER should be added to the ALUMINUM REPAIR RESIN, and both components should be mixed together, using a metallic spreader. For larger quantities, mechanical homogenization is recommended. It is essential to obtain a homogeneous mixture.

After homogenized, the product can be applied on the desired location using a brush or spreader.

When the room temperature or parts temperature is below 15°C, apply a heat source to heat the parts and the resin, at a minimum temperature of 25°C. This procedure will provide the perfect resin cure and will consequently provide maximum mechanical strength.

Related Products

Conheça Nossos ProdutosBudget for Company

Do you want to buy for CNPJ? Click the button below and speak to one of our experts.

Request a quoteFind a Store

We are present throughout Brazil, click the button below and find the store closest to you.

Find storeBuy Online

You can buy directly from our online store and receive it at your home. More comfort and agility for you.

Go to online store