Brazil stands out as one of the world’s largest grain producers, with soybeans, corn, rice, coffee, wheat and beans being the main types cultivated. But post-harvest grain losses are still high as well, occurring mainly during transport and storage. Therefore, it is essential to invest in a quality silo fence, to reduce the chances of damage.

Check below how the RR 500 ECO system is the best option for this type of service, because of its high durability, ease of application and thermal reflectance. Good reading!

Understand grain production in Brazil

According to data from the National Supply Company (Conab), Brazil should have a production of 268.7 million tons in the 2020/21 harvest. This volume is 4.2% higher than the previous crop’s record. The survey points out that the cultivated area should also have a growth of 1.3%, which corresponds to 879.5 thousand hectares more. With these numbers, it became even more evident the importance of investing in an efficient storage system, capable of contributing to the valorization of the harvest.

This is because storage can be a strategic factor to maintain the quality of the grains after being harvested, which allows greater autonomy at the time of commercialization. Because, it is possible to stock the production and sell it when prices are better, which contributes to an increase in the producer’s profits. In some Brazilian regions, it is even possible to maximize the use of the area and the machinery by planting a third crop, which is only viable with the existence of a warehouse.

However, even a world relevant country in grain production such as Brazil, suffers high post-harvest losses, especially during transport and storage. Estimates from the Ministry of Agriculture, Livestock and Supply (Mapa) and of the Food and Agriculture Organization (FAO/ ONU) indicate that 10% of all annual production is lost from harvest to final disposal. Among the main causes of post-harvest grain losses are attacks by insects, mites, birds, rodents, fungi and bacteria.

This percentage does not include qualitative losses, which are responsible for compromising the use of all the grains produced or their classification for another use with lower added value. In the case of wheat, for example, a live insect in a batch can disqualify the commercialization as a whole. Another problem is when there is a depreciation in the sale value due to the early germination of the grain, a situation derived from the unwanted entry of moisture into the silo.

Avoid post-harvest grain losses with the RR 500 ECO

To avoid post-harvest damage, producers employ some measures, such as investing in a quality seal for both the roof and the base of the silo. On the market today, there are several types of waterproofing that can be used for this purpose. However, care must be taken when choosing the product, as it will be exposed to the actions of time. It means that, a failure can mean the loss of an entire crop.

The RR 500 ECO waterproofing has anti-UVB additives in its composition, i.e. it is weather resistant (UV rays). This is one of the reasons for increasing the useful life of the substrate with the application of this solution, which can reach up to 15 years. By doing this, the frequency of maintenance also decreases, offering a better cost and benefit in the long term.

In addition to the anti-UVB additives in the composition, the liquid membrane based on the hybrid technology does not dilute in water, ensuring a completely watertight seal. This feature is also a differential at the time of application, because as it cures in contact with humidity, maintenance does not run the risk of being lost even in the middle of the rain.

Take a productivity leap with a simple application

In addition to the lower number of maintenance, they will be faster and more efficient. That’s because the RR 500 ECO was designed for an easy and agile application, already being marketed ready for use. In other words, to apply this product it is only necessary to open the can, homogenize with a spatula or mechanical stirrer and apply it on the substrate as long as it is clean and there’s no cracks on it. Its performance varies if it is applied with a brush, roller or airless, system, but a 4kg can may be waterproof up to 8m², considering the recommended two coats of the product.

As already mentioned, the RR 500 ECO was developed with hybrid technology, a high performance raw material that guarantees high adhesion power. This means that on properly cleaned surfaces, it is not necessary to use a primer, eliminating an application step. To meet cleaning requirements, the ideal is to use water to remove all dust, oil and loose particles from the surface where the product will be applied.

Another feature that contributes to faster application is the shorter curing time between coats of two hours. It means that, depending on the size of the area, it is possible to carry out the entire waterproofing service in one day. The shortest final curing time, only 48 hours, contributes to faster site clearance. In short, using the RR 500 ECO is a productivity leap, because it allows you to do more in less time.

Thermal reflectance that can generate savings

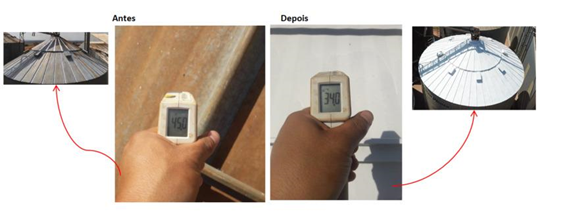

Another benefit of this solution, which can even generate future savings, is its thermal reflectance. As it reflects up to 89% of the sun’s rays, there is a reduction in the use of the ventilation system, reducing costs without harming the thermal comfort that the environment needs. An example of this is an application made in a silo in Mato Grosso do Sul, where the temperature reduction reached 25%.

In short, a well-sealed silo with quality products can be the difference between a lost crop and the best quality grains for sale and consumption. When choosing products for sealing the roof and base of the silo, it is essential to search which products will offer the durability and watertightness that this application requires. Less working time because of easy applicability is a bonus, in addition to features such as thermal reflectance that can generate future gains.

The waterproofing RR 500 ECO offers these and other benefits! Contact us and guarantee the watertightness of your silo right now.

Comentários

Ainda não há comentários. Seja o primeiro a comentar.