Stopping the production line because of a floor repair no longer has to be a problem. Do like Projefer, who used FR 117 Mortar in maintenance and managed to clear the place 600% faster. Keep reading for details!

Client:

Located in São José dos Campos/SP, Projefer has more than 10 years of experience in installations and maintenance of buildings and metal structures.

Problem:

For any company, stopping the production line because of a repair is a huge waste of money and time. The situation is even worse when these stops are recurring, as the loss increases even more. Unfortunately, this was the case for a Projefer customer.

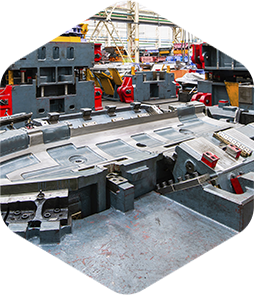

Due to heavy traffic from pallet trucks, forklifts and cargo carts, the company’s floor had cracks and holes. Some of these problems arose in the region of the metal rails, which is common because of the vibration of the place. Several repair mortar options had already been used to solve the problem, but the pathologies were only eliminated for a short period of time. This is because conventional repair mortars do not have a good adhesion to metallic substrates, such as a rail.

In addition to not solving the problem permanently, the time to clear traffic at the repaired site was very high. I.e. for 7 to 28 days (average curing time for conventional repair mortars) the area that underwent maintenance remained isolated, which hindered the operation of the production line and/or stock.

For this reason, Projefer looked for a solution for its client that would permanently eliminate the problems. The product used should also have the least possible interference in the company’s production routine, so as not to further increase the financial and time losses.

Solution:

Projefer sought out the specialist Hard Eliabe Viana after seeing a video about Epoxy Mortar FR 117. He wanted to know more about the product to understand if the material could solve his customer’s problems. To learn more about the product’s performance better, Projefer tested the material in a small area of ??its customer.

By performing this test it was possible to prove two characteristics of the FR 117 that would make all the difference for the Projefer customer. The first was the excellent adhesion of the product, which, as it is an Epoxy base, would offer a more resistant repair, even on metal rails. So the problems wouldn’t return after a few weeks and the company wouldn’t have to think about maintaining the floor for a long time.

The second and one of the most important features was the much faster repair. As FR 117 reaches its maximum hardness of 60MPa in less time, it is possible to clear the repaired area for heavy traffic in just 24 hours. Compared to other products with the same purpose, the release occurs 600% faster, requiring less isolation time and consequently less interference in the production line.

In addition to that, the product was developed to be easy to apply, aiming at high productivity. Therefore, the FR 117 is supplied in a package with the exact amounts of each component, eliminating the time spent on calculating the dosage. Its application is also very simple and fast, as you can see in the video.

After the test, 102 buckets were purchased to carry out the repair in the areas with metal rails.

Conclusion:

By using the right solution, Projefer was able to deliver a quick and lasting repair to its customer. After almost a year of maintenance on the metal rails, the problems did not return, thus eliminating rework and financial expenses. In addition to that, by using a product designed to ensure maximum efficiency, the company did not need to isolate the repaired area for more than a week, disrupting the factory’s routine. Light traffic could be released in four hours and heavy traffic in just 24 hours.

Do you want to have the efficiency and quality of the FR 117, just like Projefer? Talk to a Hard specialist and learn how our solutions can make your day to day easier.

?

Comentários

Ainda não há comentários. Seja o primeiro a comentar.