Hybrid grout for porcelain tiles – ICOM technology

Infinity Porcelain Grout is a hybrid, composite-based, ultra-thin grout, suitable for applications in porcelain tiles, decorative ceramics and tiles in internal areas. It can be applied to leaks from 1 to 4 mm thickness. The super smooth finishing turns cleaning into a quick and easy process. It has anti-mold and anti-fungal additives, and is also completely waterproof. It doesn’t stain and can only be cleaned with water.

Easy cleaning with just water

The porosity-free material inhibits the accumulation of dirt, prevents stains and makes cleaning much faster.

Anti-fungus and anti-mold

Its 100% waterproof composition and additives fight fungi and mold, while also being completely resistant to cleaning chemicals.

Quick and easy to apply

Application, finishing, and cleaning. These 3 steps are enough to have an easy application and an extremely smooth finishing.

Hard Group

For over 35 years, our company has been a national reference in metal and pre-molded construction markets, civil construction, modeling industry, prototyping and tooling. Headquartered in Joinville – Santa Catarina

Benefits

100% WATERPROOF

100% WATERPROOF

Extremely smooth finishing

Extremely smooth finishing

High durability – up to 10 years of Reference Useful Life (VUR)

High durability – up to 10 years of Reference Useful Life (VUR)

ANTI-FUNGUS AND ANTI-MOLD

ANTI-FUNGUS AND ANTI-MOLD

Flexible

Flexible

Easy cleaning with just water

Easy cleaning with just water

Does not scratch the porcelain tiles

Does not scratch the porcelain tiles

Quick and easy to apply (2x faster than cement and acrylic grouts and 4x faster than epoxy grouts).

Quick and easy to apply (2x faster than cement and acrylic grouts and 4x faster than epoxy grouts).

ULTRA THIN – Can be applied to 1mm leaks.

ULTRA THIN – Can be applied to 1mm leaks.

Applications

Package

- 400ml cartridge – provided with nozzle for application

| Porcelain tile dimensions | Leak width | |||

| Dimensions (W x L) | 1 mm | 1.5 mm | 2 mm | 3 mm |

| 300 x 150 cm | 45-48 m² | 30-32 m² | 22-24 m² | 15-16 m² |

| 260 x 120 cm | 37-40 m² | 25-26.5 m² | 18.5-20 m² | 12.5-13.5 m² |

| 200 x 100 cm | 30-32 m² | 20-21 m² | 15-16 m² | 10-11 m² |

| 180 x 90 cm | 27.5-29 m² | 18-19 m² | 13.5-14.5 m² | 9-9.5 m² |

| 150 x 100 cm | 27-28 m² | 18-19 m² | 13-14 m² | 8-9 m² |

| 120 x 120 cm | 27-29 m² | 18.5-19.5 m² | 13.5-14.5 m² | 9-9.5 m² |

| 100 x 100 cm | 22-24 m² | 15-16 m² | 11-12 m² | 7-8 m² |

| 90 x 90 cm | 20-22 m² | 13.5-14.5 m² | 10-11 m² | 6.5-7.5 m² |

| 80 x 80 cm | 18-19 m² | 11-12 m² | 8-9 m² | 5-6 m² |

| 80 x 40 cm | 12-13 m² | 8-8.5 m² | 6-6.5 m² | 3.5-4 m² |

| 60 x 60 cm | 13-14.5 m² | 9-9.5 m² | 6.5-7 m² | 4.5-5 m² |

| 60 x 30 cm | 9-9.5 m² | 6-6.5 m² | 4.5-5 m² | 3-3.5 m² |

| 50 x 50 cm | 11.5-12 m² | 7.5-8 m² | 5.5-6 m² | 3.5-4 m² |

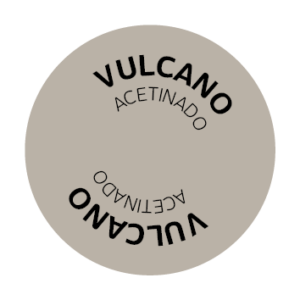

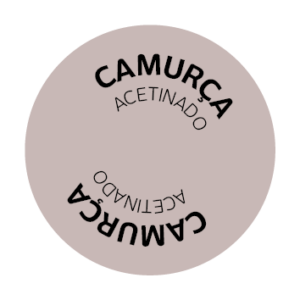

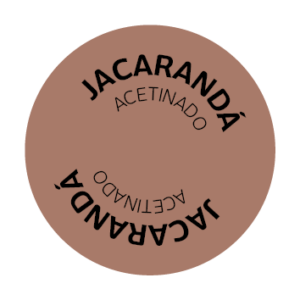

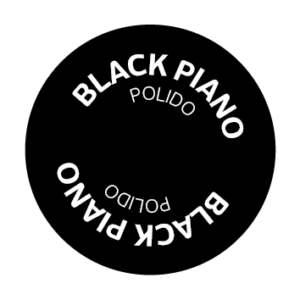

Colors:

- Chemical Base: Hybrid grout with ICOM technology

- Worktime: 20 – 40 min.

- Curing Time: 6 to 10 hours

- Application Temperature (surface): 5°C to 35°C

- Liberation for light traffic and contact with water: 10 hours

- Liberation for heavy traffic: 24 hours

- Storage life: 24 months

| 1. Leak must be 2 to 3 mm deep. To do so, in case of reconstruction, remove the old grout with the Hard Grout Extractor. | |

| |

2. In case of new flooring, remove excess mortar with the Hard Leak Cleaner. |

| |

3. Afterwards, do not forget to clean the dust with a brush or vacuum cleaner. |

| |

4. For rough floors, apply the Hard Grout Release Agent on both sides of the leak. To prevent the release agent from entering the leak, always do it longitudinally. |

| |

5. Remove the cartridge cap and connect the nozzle. After that, place the cartridge into apply position and cut the nozzle at 45º. |

| |

6. Discard 15 cm of the product. |

| |

7. Then apply grout to the leak evenly. |

| |

8. Immediately afterwards, perform the finishing process in continuous lines, while applying pressure with the Hard Finishing Spatula. |

| |

9. After 8 hours, remove the burrs using the Hard Cleaner Spatula. |

| |

10. And it’s done! Your application is complete. |

Online calculator

Online calculators that simplify the calculation of the quantity of products to be used in the project and/or construction.

Calculate now

Related Products

Conheça Nossos ProdutosFrequently Asked Questions

Once Infinity is porosity-free, there is no build-up of dirt or staining. Therefore, it is very easy to clean, can be done with just water, and does not need aggressive products. That’s why, the use of bleach is not recommended for cleaning Infinity grout, as it may alter its color.

Yes, you can. Now it is easy to apply grout to rough coatings. You will only have to apply a release wax on both sides of the laying joint before applying your Infinity Grout. It is important that the release agent does not penetrate the joint, so always apply it lengthwise. By doing it, in the final finishing stage, you will have no problem removing the burrs.

We have a Grout Remover available in our Infinity line, to learn more, access click here. Remember that if your coating is completely smooth, this step is not necessary. Watch the video below to learn how to use the Infinity line products correctly.

Did you apply Infinity grout and there was product left in the tube? Don’t worry! You can store your grout to use again later. You will just have to be careful when storing your product.

After opening the material, store the lid for closing the grout later. Remember to discard the mixing nozzle after use, as the Infinity Grout cures in there. Store the tube in a dry, clean environment at temperatures between 10°C and 25°C. It is also important to keep the product away from heat sources.

Since Infinity Grout cures inside the mixing nozzle, to reuse the product, you need extra nozzles. This item is available in our virtual store, check it out click here.

Budget for Company

Do you want to buy for CNPJ? Click the button below and speak to one of our experts.

Request a quoteFind a Store

We are present throughout Brazil, click the button below and find the store closest to you.

Find storeBuy Online

You can buy directly from our online store and receive it at your home. More comfort and agility for you.

Go to online store